Injection Compression Molding Process

EXPERT-TIPYou are working in the automotive, electronics, optics or medical industry and want to analyse your process precisely but at the same time obtain reliable information regarding the delay time, pressure and shrinkage behavior as well as the influence of embossing? Then you should take a closer look at the Moldex3D ICM module ...

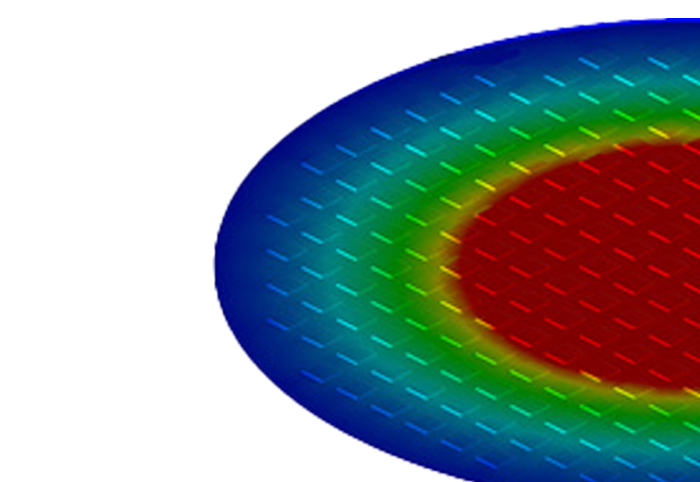

Injection-Compression molding (ICM) not only keeps the advantages of conventional injection molding but also yields additional molding advantages, such as increasing the reproduction of micro-surface feature and reducing flow distance/wall thickness ratio, etc. However, there are also more processing parameters needed to be carefully adjusted in order to get a well-molded part. For example, late compression sometimes causes the melt penetrating to parting line, while early compression sometimes causes incomplete filling. Having a powerful simulation tool is therefore crucial for users to successfully implement ICM process.

The injection compression molding module enables the user to precisely analyse both the process and the requirements of the injection compression molding process. Furthermore, a coupling to the Optics module is possible.

Would you like to learn more about simulation possibilities regarding injection compression molding and optics? Then take a closer look at our article „Mehr ist weniger“ or contact us: 0241 565 276-0 / email to info@simpatec.com .