Analysis, verification and optimization of the encapsulation process of microchips

EXPERT TIP

The trend towards intellectualization and the desire for electric vehicles is creating an increasing demand for reliable, high-performance IC product performance in the global industry. Advanced IC packaging technology is essential and plays an increasingly important role in the manufacturing process.

IC Packaging helps designers to fully analyze the chip encapsulation process from filling, curing, cooling, to advanced manufacturing demands, such as underfill encapsulation, post-molding annealing, stress distribution, or structural evaluation. Significant molding problems can be predicted and solved upfront, which helps engineers enhance chip quality and prevent potential defects more efficiently.

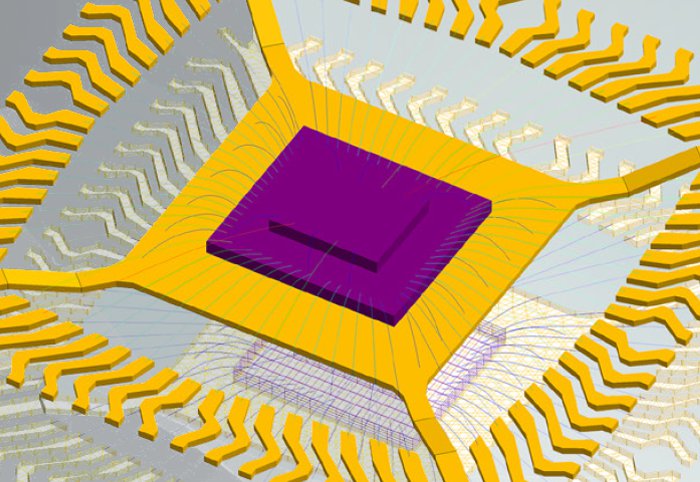

Plastic Chip Encapsulation is a molding process where chips are being capsulated with Epoxy Molding Compound (EMC) to prevent physical damage or corrosion. This process contains the interconnection between microchips and other electronics (so-called wire bonding), curing phenomenon of thermoset material, and various control management of process conditions.

Due to the complexity of multiple material components, such as EMC, chip, or leadframe, and high wire density, many challenges and uncertainty have been brought to the Chip Encapsulation process. Common defects include incomplete fill, welding lines, air traps, voids, wire sweep, paddle shift, package warpage, etc.

We will gladly answer your questions and inform you in detail about IC-Packaging! Please contact: 0241 565 276-0 or send an email to sales@simpatec.com .