Moldex3D iSLM

Smart data management platform

The next generation of a data management platform for injection molding

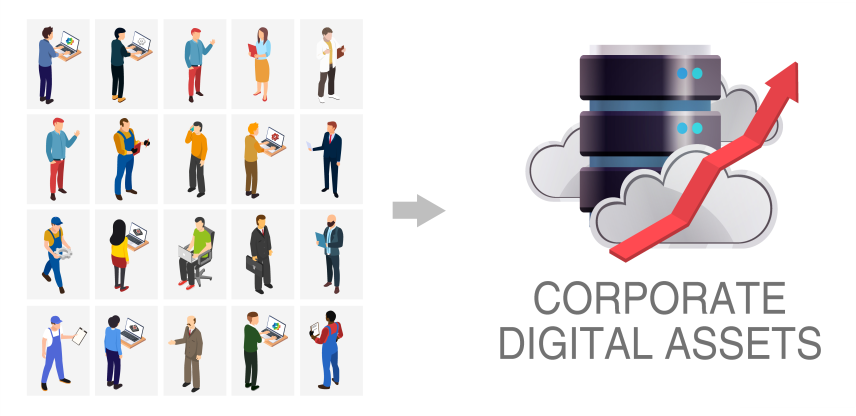

iSLM (intelligent Simulation Lifecycle Management) is an intelligent and interactive data management platform designed specifically for plastic engineering companies. It records and visualizes every phase of the mold development data online. With iSLM, workflow information can be shared across departments to reduce communication gap and improve teamwork efficiency.

Key features

_ Centralized data management that makes data acquisition easier than ever

_ Transforming users' experiences into valuable digital assets and increase the core competitiveness of the company

_ Sharing timely information across different team members, including part designers, CAE engineers, mold designers, and on-site process engineers

_ Efficiently monitoring work progress and following up on each task

_ Web-based (private) cloud service that allows quick access anytime, anywhere

_ Flexible and user-friendly interface with customized management systems that meets different company's needs

_ Transforming users' experiences into valuable digital assets and increase the core competitiveness of the company

_ Sharing timely information across different team members, including part designers, CAE engineers, mold designers, and on-site process engineers

_ Efficiently monitoring work progress and following up on each task

_ Web-based (private) cloud service that allows quick access anytime, anywhere

_ Flexible and user-friendly interface with customized management systems that meets different company's needs

How can iSLM support you?

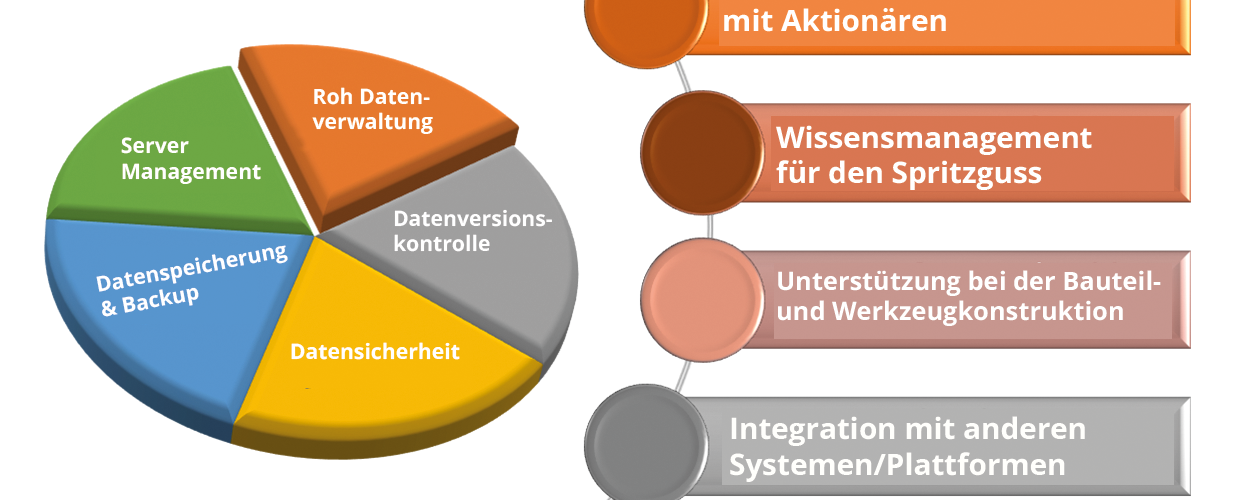

Most problems during production of injection molded components arise over the course of the component development. iSLM captures and centralizes all important information at every stage of the development process. The timely and cross-departmental transfer of know-how optimizes communication as well as the workflow and thus enabling a more efficient teamwork.

Security management

Moldex3D iSLM is an interactive 'private-cloud-based' data management platform that ensures your data security. Additonally, centralized data storage allows for easier IT management and data backup. Another great feature is that the data access can be defined based on user rights, this goes as far as access rights for customers or supplier user-defined permission assignments for each user account, practically also to be able to administer entire teams.