Utilizing Sequential Valve Gating to Improve Surface Quality

EXPERT-TIP

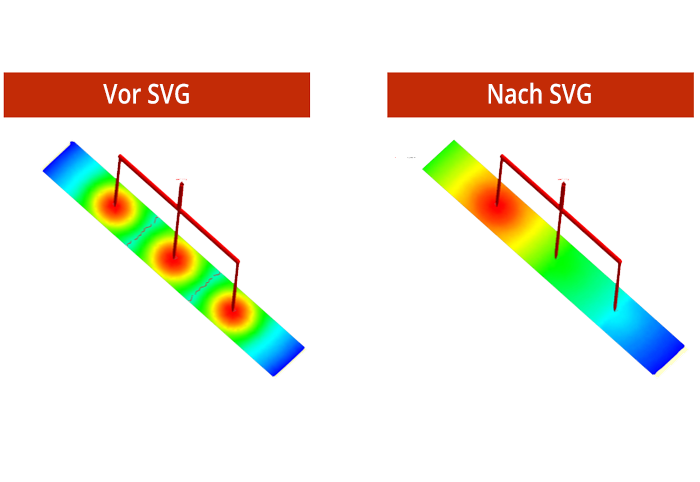

Did you know that Moldex3D Advanced Hot Runner Analysis and its pin movement simulation allows you to consider the influences of pin position and velocity to optimize their sequential valve gated hot runner systems? These technical features additionally offers the possibility to evaluate if and how, the dynamic needle movement helps to prevent flow marks and other cosmetic defects ...

Talking about cosmetic exterior components, especially in automotive industry, high-quality surface will be in the spotlight. Sequential Valve Gating (SVG) becomes one of the best options in injection molding to produce perfect part surface. SVG is a common technique that the timing and the order of cavity fill pattern can be fully controlled to prevent surface defects and improve part performance.

Interested?! Please contact us at 0241 565 276-0 or send an email to info@simpatec.com.