Good material data = High-quality simulation results

ESPECIALLY FOR OUR USERS

The quality of material data is essential to acquire good quality simulation results. Whenever a material is selected for a given simulation task, the material card must be examined very thoroughly to discover any possible inaccuracies or errors in the material data.

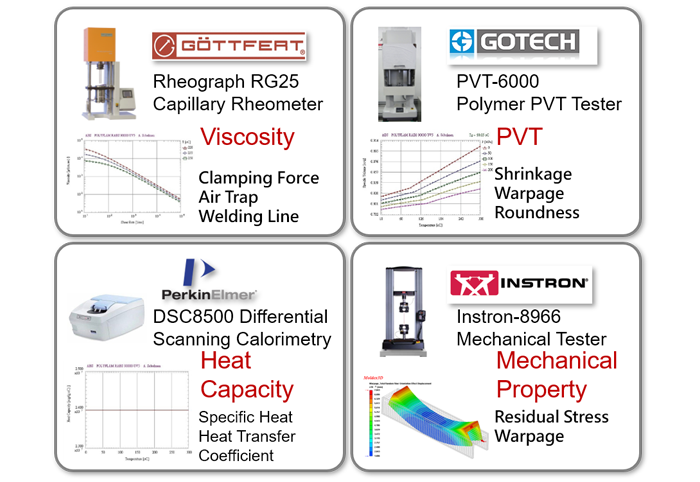

The effect of the material data quality on the results can be sorted to two categories: filling and packing that is warpage and shrinkage analysis. The possibility of incorrect material data resulting in erroneous result is much higher in the latter case. The first part of assuring the quality of the data is checking its sources. If the data came from the material supplier, that may be an indicator of reliability, but this is not a guarantee of quality in itself, as the characterization capabilities of material manufacturers vary greatly. Usually the results from independent laboratories (e.g. CoreTech System) are the most reliable ones.

Among the possible considerations are the following: compounds with high fiber or filler content may yield better results with the Herschel-Bulkley Cross viscosity model instead of the more commonly employed Modified cross Model. The L/D ratio of reinforcing fibers must be chosen as correctly as possible, this is particularly important for long fiber reinforced grades. If no data is available for a particular material, it may be appealing to use substitute materials chosen on the basis of similar MFI, density etc. However, this must be done with extreme caution, as this leads to very bad results in some cases.

The most important inputs for warpage calculation are pvT and the mechanical properties. Literature and generic data should be avoided here. In every case the consistency of this data (their correspondence to the bulk and melt density, crystallization and ejection temperatures etc.) must be examined. Another important point is to have accurate and preferably temperature dependent thermal conductivity and heat capacity.

SimpaTec is at your disposal for acquiring and verifying material data, including the fitting of model parameters.

Deeper insights are of interest!

Please contact us: + 49 (0)241-565 276-0 or send us an email to info@simpatec.com .