Special GAIM/WAIM process in Moldex3D

ESPECIALLY FOR OUR USERSYou are working with the gas injection (GAIM) or water injection method (WAIM) and want to simulate these methods, then Moldex3D can help. Special modules are integrated in Moldex3D for both processes.

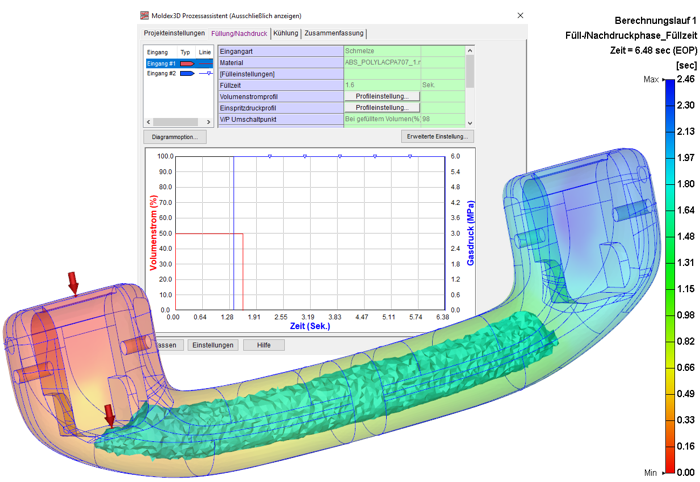

Gas injection technology (GAIM) and water injection technology (GAIM) are fluid injection technology processes. Here, the molded part cavity is first completely or partially filled, as in the conventional injection molding process, and then either gas or water is injected as a fluid. Moldex3D enables the simulation of the entire process from mold filling to the injection of the fluid (2nd phase). In the second phase, the fluid displaces the polymer melt and creates a cavity in the molded part. The use of these techniques extends the design scope and enables considerable material savings with comparable functionality. The holding pressure effect can be extended by the internal pressure beyond the sealing point, which counteracts shrinkage and warpage. Cycle times can also be reduced due to the additional cooling effect of the fluid.

Both processes can be simulated in Moldex3D using the corresponding modules.

The wall thickness distribution is one of the results obtained with this process. This allows the possible material and weight reduction to be determined and the geometries to be exported for a structural-mechanical simulation. The advantageous effects on the process (cooling times) and the distortion of the component can also be precisely analyzed.

For the simulation, the component including sprue and injector as well as a possible overflow cavity are modeled. The temperature control can also be integrated in the same way as the conventional injection molding process.

Durch variable Prozesseinstellungen, wie Volumenstrom, Füllgrad, Material- und Werkzeugtemperatur sowie fluidspezifische Einstellungen wie Fülldruck, Halte- und Verzögerungszeit kann mit Moldex3D der Prozess und die Restwandstärke optimieren.

Please contact us: 0241 565 276-0 or send an email to sales@simpatec.com.