Improved software capabilities and enhanced analysis accuracy

EXPERT-TIP

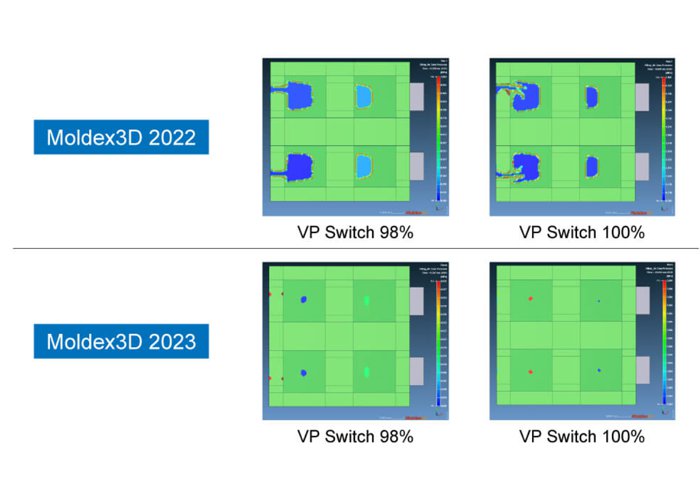

It is a major endeavor to continuously improve the simulation capabilities and performance of Moldex3D. This goal has successfully been established in Moldex3D 2023. Material property data plays a significant role in obtaining accurate injection molding simulation results. Therefore, the Moldex3D Forming Technology R&D Center has conducted real injection experiments using nearly 400 different materials to optimize parameters in the material library, enhance reliability, as well as making the results of molding analysis even closer to reality.

But impressive newly conducted achievements in terms of molding analysis don’t end here. In this current release users can look forward to astonishing upgrades for venting analysis including compressibility and air temperature calculation. With just a few clicks one can accurately simulate the temperature and pressure changes of air in the mold cavity during the filling process allowing users to plan and compare various venting designs, avoiding defects such as short shots and burn marks.