Clamping force

ESPECIALLY FOR OUR USERS

You have a product in the development phase but you don't know if your machine is suitable for burr-free components?

Since the maximum clamping force determines, amongst others, the size of the mold and component, it serves as an important parameter to classify injection molding machines.

Injection molding is a high-pressure application in which plastic is continuously pressed into an empty volume. As the plastic moves the flow resistance increases, requiring the screw to apply more force. This increase in force can lead to a phenomenon known as burr, which is typically observed as material escaping at the mold parting line in plastic moldings because the machine's clamping system cannot withstand the pressure applied by the machine. The ability to predict the clamping force before the mold goes into production is critical to minimizing any problems with burr while keeping the size of the machine appropriate to reduce production costs.

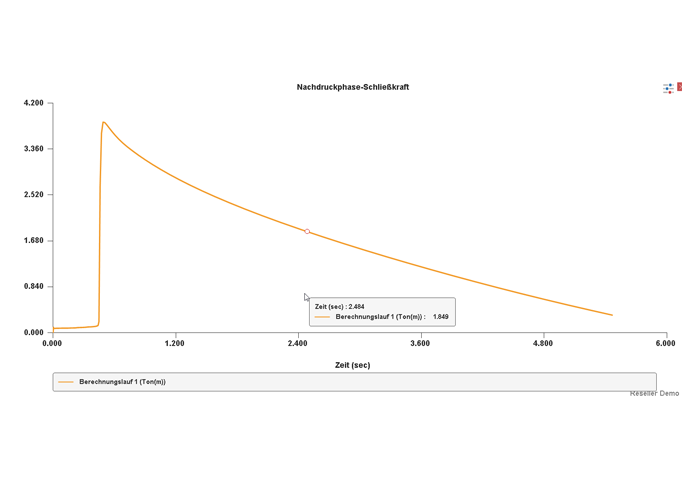

During simulation there is also a result that represents the clamping force in the XY plot.

This result shows the progression of the clamping force over the filling time. Note that this value is the calculated required clamping force; it is not the force that the injection molding machine distributs.

You can use this result to identify potential burr problems. Experience shows that if the calculated clamping force is more than 70% of the maximum clamping force of the machine, there it is very likely that the plastic melt will be forced out of the cavity and thus causing a burr.