Better simulation results by means of thorough modeling

ESPECIALLY FOR OUR USERS

The quality of the simulation results depends on the quality of the simulation model. This applies all the more if inserts exist in the modeling and/or a core offset is to be taken into account in the process simulation. Moldex3D Studio 2023 includes a new function that makes modeling easier and more efficient. Find out more about this new function in our article ...

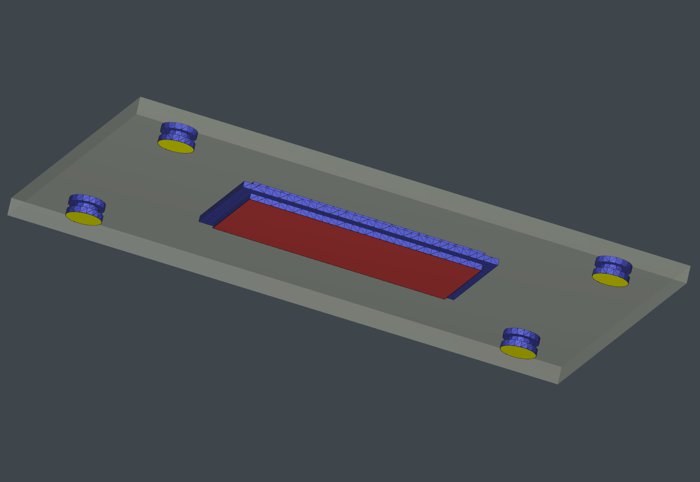

When modeling with component inserts, it is important that the contact surfaces are correctly meshed. There must be a so-called "matching faces" mesh between the two objects. A "matching faces" mesh is defined by the fact that all mesh nodes on the contact surfaces of the two objects match. This also applies to a two-way fluid-structure interaction analysis (FSI for short) to determine the core offset.

In Moldex3D Studio 2023, automatic matching faces meshing is available in the generation sequence of the individual model objects. Depending on how well the object geometries fit together, this matching faces option may not be successful. In addition, this option generally changes the mesh node topology of the entire cavity mesh. For users who want more control over the meshing and for whom the first option was not successful, there is now the new "Automatic copy/paste" function in the "Mesh repair" area. This function allows you to automatically adjust the surface meshes of the cavity and the insert or mold core with just a few clicks and without changing the remaining node distribution of the cavity.

By using the matching faces principle in modeling and the new Auto Copy/Paste function, you can achieve more accurate simulation results in less time. If you have any questions about using the function or the matching faces, please do not hesitate to contact us.

Please contact us: 0241 565 276-0 or send an email to sales@simpatec.com.