Validation & verification of material & structural behavior using computer tomography

ESPAECIALLY FOR OUR USERS

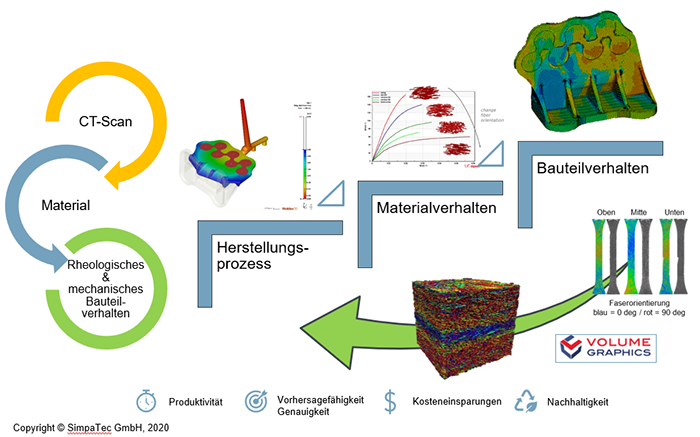

Compared to non-reinforced materials or steel, composites have a complex material behavior due to their microstructure that defines stiffness, strength and failure. Furthermore, effects other than the expected behavior can occur based on the type of manufacturing process. In order to model the material cards optimally, computer tomography can reliably provide the required input data ...

In order to optimize a component design, sufficient information about the structural behavior is important. The integrative simulation by means of the coupling of manufacturing process, extended material modelling as well as the structural-mechanical FE analysis plays an essential role. The integrative simulation provides valuable information about the structural behavior of the component, which allows optimization measures to be derived and critical areas to be identified.

The manufacturing process defines the microstructure in case of orthotropic or anisotropic material behavior and thus determines the basis for the later structural behavior of the component. Due to the fact that new materials are continuously being developed for specific applications, the complexity of material behavior also increases. New compounds with a wide range of additives enable the material to deliver its optimum performance under the component's operating conditions. However, it is possible that the compound will still behave as planned and show unexpected effects. This phenomenon usually occurs as soon as simulation and reality are verified and validated. Subsequent deviations in component behavior, despite a state-of-the-art approach, are often due to the input data. The cause is usually the description of the material behavior in the material card. In order to adapt the modeling to the real behavior, experimental data regarding the microstructure as well as classical tests are necessary.

With the help of CT scans, the microstructure can be measured and adjusted at both macro and micro level and, if necessary, optimization measures can be taken regarding the simulation. With the information from reality it is possible to adjust or calibrate the mechanical material behavior.

Based on the experimental data sets, a complete adjustment of the process chain can be carried out. The information about the real microstructure on the component level shows the agreement between prediction accuracy of the process and with the help of a µCT scan the material behavior can be analyzed exactly.

An overall added value results from the higher result quality of predictions from the calculation simulations, which allows early adjustments, optimizations of components, products or assemblies. Thus cost reductions, reliability, shorter production times/implementations are realizable.

We are happy to support you in any consulting matters as well as for the implementation of tests and measurements.