Too warm / Too cold - the "few degrees" difference

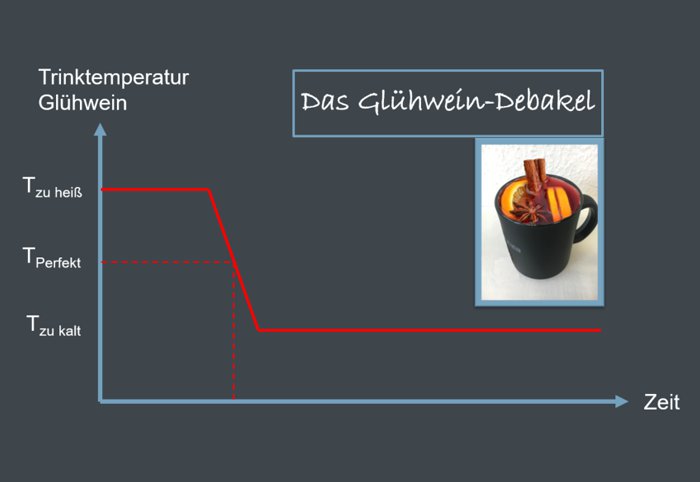

ESPECIALLY FOR OUR USERSAdvent is here and it's really getting colder outside. Small differences in temperature are quickly noticed: hat, scarf, gloves? - yes/no/maybe. By the way, this also applies to glogg at the Christmas market - first it’s too hot and then it gets too cold too quickly. A few degrees make all the difference!

Well, with plastics it’s precisely the same! The Moldex3D plastification module provides insights about the "few degrees difference" regarding the melt temperature.

The basis for a successful injection molding process is the plastification of the material within the plasticizing unit of the injection molding machine. For starters the plastic granulate is filled into the hopper. The rotation of the screw in the barrel carries the material towards the nozzle. The resulting frictional heat causes the thermoplastic material to melt along the screw. Further heat is supplied by the heater bands along the barrel. Overall, this results in a plastic melt at the nozzle with a specific melt temperature, which depends on the plastification process.

The melt temperature has a major influence on the filling behavior during injection: Viscosity changes with temperature, which in turn affects injection speed or pressure. Amongst others, this can lead to short shots or increased shear stress.

The Moldex3D plastification module takes this important part of the injection molding process into account, thus providing more accurate information about the melt temperature. For this purpose, geometric dimensions of the screw, heating bands, as well as screw speed can be implemented and the process can be calculated with the material to be applied. In addition to the melt temperature, shear rate and shear stress profiles, temperature profiles, velocity profiles and the melt behavior are output as results and thus represent a stress history of the material. Furthermore, the knowledge of the resulting melt temperature in particular leads to a more precise filling calculation - sometimes it's "just a few degrees" that counts!