Specialities to be considered when measuring thermosets

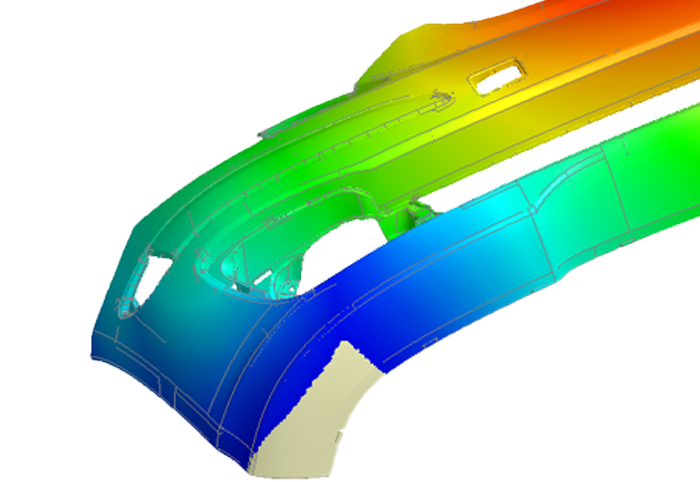

ESPECIALLY FOR OUR USERSThe injection molding simulation of thermoset polymers raises more difficulties than thermoplastic injection molding, because the crosslinking which takes place simultaneously with the molding process is continuously altering material parameters throughout the molding process. This poses difficulties particularly in the material characterization and creation of the material data.

Thermosets are distinct from thermoplastic polymers in one major respect: their processing includes the chemical reactions of cure. Cure begins with the growth and branching of chains. As the reaction proceeds, the increase in molecular mass accelerates, and eventually several chains become linked together into a network of infinite molecular mass. This applies to all such technologies: rubber processing, chemical foaming molding, compression molding, encapsulation etc. The knowledge of curing kinetics is the precondition of rheological investigations and the creation of the material models; therefore, the curing model must be determined very accurately. Another important factor is that if the shrinkage, warpage and residual stresses are to be calculated, the curing shrinkage must be considered. This is the component of the shrinkage which is not related to the compressibility or thermal expansion of the material, but is caused by the crosslinking. This is represented in the pvTc models used instead of the pvT applied for thermoplastics. Both the curing kinetics and the pvTc can be measured accurately, thanks to its special equipment.

Interested?

Please contact us: + 49 (0)241-565 276-0 or send us an email to info@simpatec.com