Simulate fluid injection molding processes - Moldex3D GAIM/WAIM

ESPECIALLY FOR OUR USERSDo you have warpage problems with your plastic parts and already have experience with gas injection or water injection processes?

With the GAIM/WAIM modules Moldex3D offers the possibility to simulate these fluid injection processes. Thus, complex experiments as well as material and manufacturing costs can be reduced and the processes can be perfectly designed.

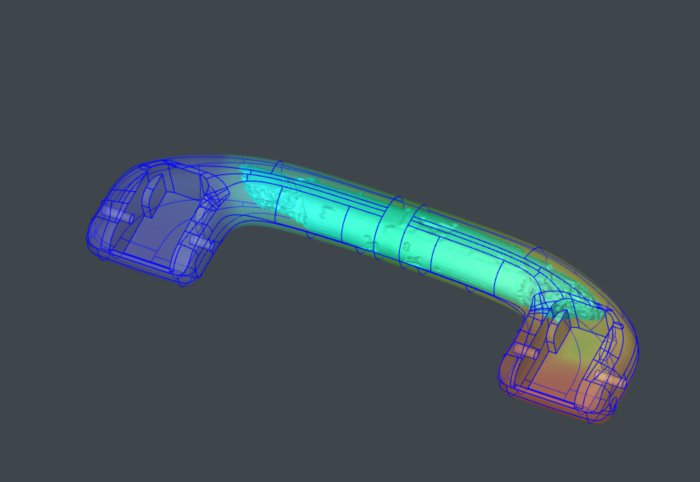

Both processes the gas injection technology (GAIM) and water injection technology (WAIM) are fluid injection technology based. Here, just like in the conventional injection molding process, the molded part cavity is first filled completely or partially and then either gas (GAIM) or water (WAIM) is injected as a fluid. Moldex3D enables the simulation of the entire process from starting with the filling of the mold as a first step and then followed by injecting the fluid (2nd phase). In the second phase, the fluid displaces the polymer melt and creates a cavity in the molded part. One of the effects is the resulting wall thickness distribution. This enables to determine possible material and weight reduction and also allows the geometries to be exported for a structural-mechanical simulation. Furthermore, beneficial effects on the process (cooling times) and the warpage of the component can be analyzed in detail.

Deeper insights are of interest!?

Please contact us: + 49 (0)241-565 276-0 or send us an email to info@simpatec.com.