Optimizing the quality of injection molded components

ESPECIALLY FOR OUR USERS

You need meaningful criteria that enable you to assess and optimize the component quality of your injection molded parts both mechanically and optically! Then the position of the weld line can be the appropriate criterion. This can be mapped in no time with Moldex3D ...

A weld line occurs when two or more melt fronts meet during the filling phase. If the melt fronts cool down in the course of this, they no longer bond optimally. The timing of the melt confluence thus strongly influences the weld line, so that the strength of the injection-molded part can be significantly reduced at the weld line position. This leads to a weak point in the component. Therefore, the weld line is weaker when the melt meets only at the end of the filling phase. Thus, the strength of the weld line can be assessed by the melt temperature at the weld line and a so-called weld line angle. The smaller the angle, the weaker. This also applies to the weld line temperature, which leads to weakening of the weld line if it is greater than or equal to the melt temperature at the end of the filling phase.

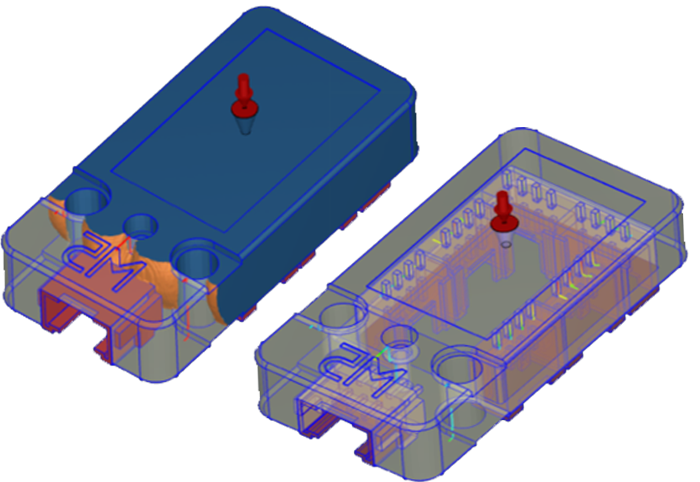

Moldex3D offers the possibility to determine and evaluate the position of the weld line for complex geometries as well as for models with inserts.

Just like with a standard injection molding simulation, the corresponding attributes are assigned to the components used. The modeling is preferably generated with a BLM mesh (Boundary-Layer-Mesh). Finally, the material for the molded part and the process parameters are set in the process window. The process parameters can be adjusted specifically, to the processing conditions of the materials, to optimize part quality.

The results include pressure and temperature distribution, the position of air pockets and that of the resulting weld lines in the part, at the end of the filling phase. For this purpose, two additional result plots are obtained, on the one hand the weld line temperature and the weld line angle, and on the other hand the melt temperature and the angle of impact of the melt on the weld line can be used to evaluate these.

We look forward to your feedback and should you have any further questions, we will be happy to help you.