Navigate crystallization values

ESPECIALLY FOR OUR USERSDo you know that the amount of crystallized polymer in injection molding strongly depends on the cooling rates? Use the tools in Moldex3D Studio to navigate the crystallization values in your part.

Relative crystallinity in Moldex is defined as the absolute crystallization divided by the ultimate crystallinity. When a semi-crystalline material is slowly cooled down, the amount of crystallized chains ratio reaches to the ultimate crystallinity and equivalently the relative crystallinity would be 1 (or 100%). Now, if the material is cooled down faster the crystals won’t have enough time to form and the relative crystallinity will be lower than 1.

Fast cooling occurs near the surfaces, where the part is thin, or in areas near the cooling channels. If you want to measure the relative crystallinity in your part you first should be careful that

- You have included the crystallization effect in your calculations.

- You have selected “Extend Packing Calculation to end of cooling” (Home -> Computation -> Flow/Pack -> Extend Packing Calculation to cooling phase).

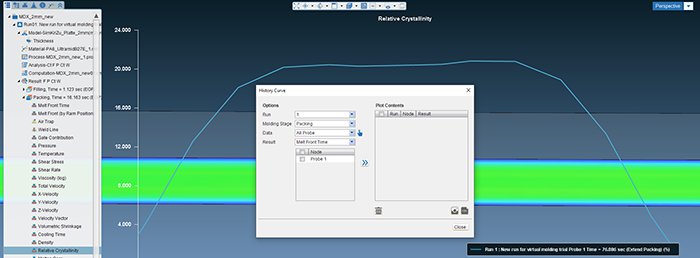

- Select the packing stage in the result toolbar.

- Go to the Result tab and select “XY Plot – Thickness”.

- Make sure the options are selected correctly: correct Run, Molding Stage Packing, Data All Probe, Result Relative Crystallinity.

- Using the probe tool (the finger sign) choose a probe node where you want to see the result. The node should be selected on top of the part.

- Select the probe and use the >> to plot the results.

Deeper insights are of interest!?

Please contact us: + 49 (0)241-565 276-0 or send us an email to info@simpatec.com . Back to overview