Moldex3D R16 - The Next Generation

With competence, experience, ambition and the use of the latest software technologies, SimpaTec mutually sets new standards in the holistic development and optimization of processes, components and tools, and will again be present at the FAKUMA in Friedrichshafen, Germany with its own stand (Hall A5, Stand A5 5003). The trade fair celebrates its 25th anniversary in October and focuses on the comprehensive range of services for the overall development and optimization of components by using up-to-date software technologies.

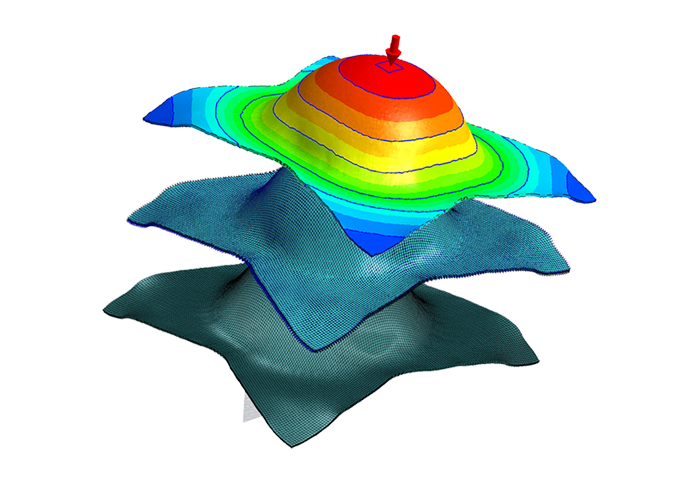

Moldex3D is the no. 1 software solution for the design and optimization of injection molding providing reliable, consistent and accurate results for the part, tool and process optimization. The new version R16 of Moldex3D has a stag full of new features and novelties which are driven primarily by customer’s feedback and which will substantially help part designers and mold makers to efficiently and effectively master their daily work whilst still achieving the best possible economic success.

Totally new prediction options for RTM

A great deal of thought and clever thinking has been put into the Moldex3D Resin Transfer Molding (RTM) simulation capabilities. For example, warp analysis for RTM parts is now supported and draping effects from LS-DYNA are considered to increase the simulation accuracy for high-quality RTM parts.

Additionally, RTM pre- and post- processing platforms have become more intuitive and user-friendly in R16, and the opportunity is given to define ply groups, boundary conditions and material groups, and to visualize the ply orientation on each layer, delivering better structural performance.

Hot Runner valve pin movement

In the new release of Moldex3D the advanced hot runner analysis has been enhanced by supporting the simulation of valve pin movement, allowing users to take the influences of pin position and velocity into account during flow simulation. This can help validate the effectiveness of using pin movement technology to prevent flow marks and other cosmetic defects.

Other important enhancements are the new triggers available when simulating valve gates. These include fill volume, timing (after V/P Switch) and Flow Front (by hot runner tip), and thus providing a considerable improvement in flexibility and accuracy in simulating the opening/closing of a valve gate.