Moldex3D 2020 - "Goes beyond simulation"

SimpaTec, one of the leading engineering and software companies in the holistic development and optimization of processes, components and tools, is proud to announce the latest release of Moldex3D. The new version not only has a new name designation - Moldex3D 2020 - but goes "beyond simulation". With this release, CoreTech clearly underlines the top position of its product as the leading software solution for the design and optimization of the injection molding process. The feature innovations are all based on customers’ needs to help conduct molding analysis in a faster and more convenient manner. Therefore, even more comprehensive, in-depth and detailed simulation options have been developed in the current release. One can look forward to considerably faster calculation times, significant improvements for RTM and foaming as well as a high-performance, team-compatible data management system (iSLM). Moldex3D 2020 makes it even easier to identify and evaluate potential sources of error in the process, tool or component, and to implement a design that is optimal in terms of cost and quality - intelligent production becomes a reality!

Usability & Speed

One of the goals is to keep pushing the boundaries to further develop committed simulation capabilities and to improve and optimize Moldex3D’s solver to reach faster calculation times. This has been achieved by refining the solver architecture of the software, which resulted in an immensely improved computational performance by which users are now able to save an enormous amount of time when conducting analysis procedures – namely more than 20%.

Additionally, many new geometrical and mesh repairing tools have been added to allow users to process geometric and mesh problems in a more convenient and faster manner, and so hence the pace of design changes is effectively enhanced.

Comprehensive advanced features

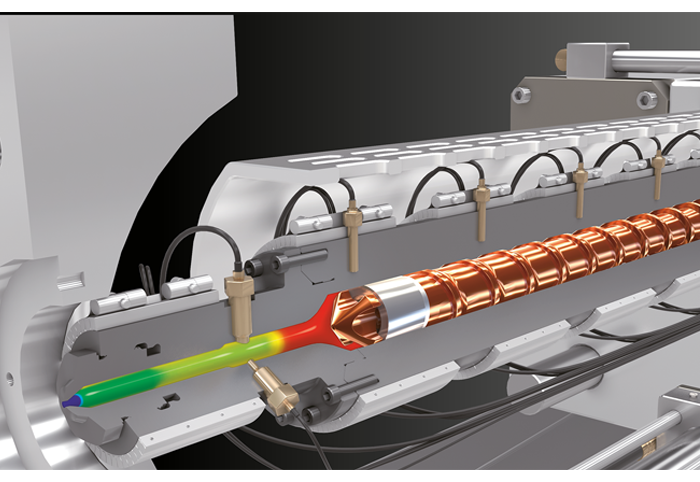

Industries are facing more severe challenges due to the rapidly changing market demands and the impact of the current global trade situation. Moldex3D provides comprehensive advanced processes to empower users to be more competitive in product innovation and development. The new release has made great leaps in the enhancement for Resin Transfer Molding options, like for example being able to consider the 2D woven fabric to achieve a prediction that is even closer to the actual warpage of the product. Furthermore, an astonishing breakthrough in terms of chemical foaming can be reported. The intense developments have really been worth while as now the module supports the analysis of dissolution and temperature for the foaming gas, as well as the reaction simulation for thermoset materials.

In addition to the breakthroughs in the RTM and the foaming module, Moldex3D 2020 also improves its simulation skills of fiber composite materials to realize changes in fiber concentration or length, which allows to capture simulation results of any alterations within the flow behavior. With this adjustment, users will be able to predict the melt flow behavior faster and thus the work efficiency will be greatly enhanced.

Smart manufacturing requires an intelligent data management platform (iSLM)

Manufacturing transformation is inevitable in the trend of smart manufacturing. A set of systematic management tools will be able to assist enterprises to collect data and centralize the management, as well as derive value from the process to enhance the team’s work efficiency! Moldex3D iSLM is a service developed to fulfill this demand.

iSLM is an intelligent and interactive data management platform designed for plastic engineering companies. The items of data management include model feature size, gate size, gate type, cooling system design, mold tryout parameters, CAE simulation results etc. Users can simply centralize the important and valuable data in the iSLM platform throughout the entire product development lifecycle.

The mold number-based storage structure easily links and tracks a bunch of data, it can help to not only visualize the CAE simulation results, but also check the on-site mold tryout experiments. Furthermore, it is possible to monitor the manufactured part quality by checking mold design related information on iSLM.

With the capacity to upload tens of thousands of data, iSLM can accommodate the team members across many involved divisions. It enables swift communication between parties making comparison of different design approaches easy and productive.

With Moldex3D 2020 you can walk on an easier path when developing and innovating products.

"With Moldex3D 2020, the development and production of components is considerably simplified", says Steffen Paul, Managing Director and responsible product manager of SimpaTec, emphasizing the new functionalities and further developments of the release. "The new version sets a milestone which literally goes 'beyond simulation'. The dispatch to our users is primarily completed. We are extremely pleased about the first initial reactions, which show us that not only the name giving conveys something fundamentally new, but that Moldex3D 2020 delivers exactly what it promises.”