Machine mode – and its advantages!

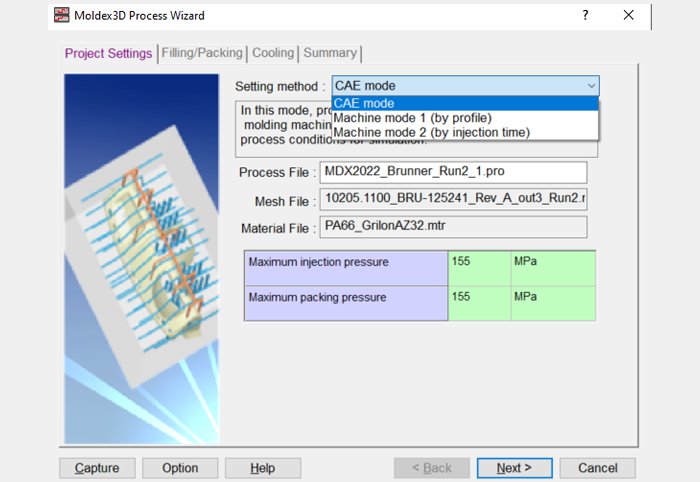

ESPECIALLY FOR OUR USERSYou want to define the injection process and the switchover point via the movement and position of the screw and consider the machine-dependent delay times in the simulation? Then use the machine mode.

The machine mode enables the description of the injection process as well as the switchover point according to the movement and position of the screw. Two different machine modes are available, which differ in the definition of the packing pressure.

There is an extensive machine database. If your machine is not listed in the system it is also possible to perform a machine characterization.

A search can be conducted either by machine name or by its parameters. After adding the machine to the user database individual parameters can be changed by a right-click on the machine. It is to be made certain that the most important parameters of the process description correspond with your machine. (Screw diameter, screw stroke, shot weight, injection pressure, injection speed).

The settings injection unit, clamping unit, general and screw information offer the possibility to include further details in the simulation. For a simple simulation in machine mode, the setting of this information can be omitted.

The filling phase can be set via 'Flow rate profile'. Four options are available for this. The injection time is automatically calculated based on the flow rate. It should be identical or approximately identical to the injection time from the real process.

Please contact us: 0241 565 276-0 or send an email to sales@simpatec.com .