How to get the most out of simulation

++ EXPERT TIP ++

Test the FULL FUNCTIONALITY of Moldex3D until the end of the year when purchasing a basic module!

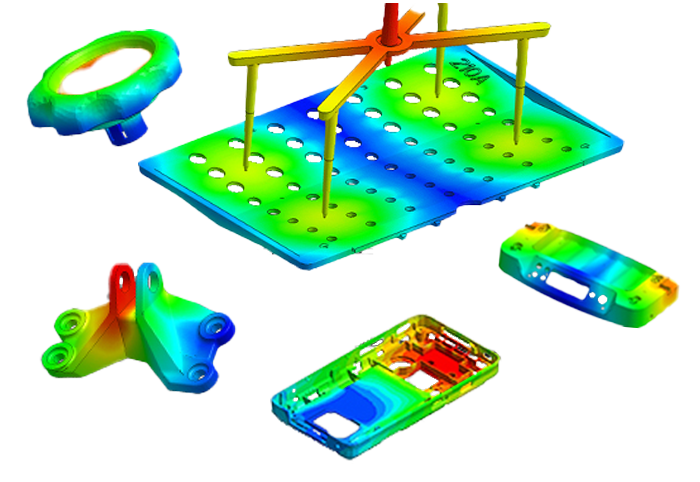

A good simulation starts with the filling. According to this headline SimpaTec, being a competent engineering and software partner for innovative methods and solution concepts for the plastics processing industry, at present offers a smart introduction to the injection molding process simulation using Moldex3D. By already purchasing the Moldex3D basic module one is in a position to quickly and reliably identify the first weak points of the component or the tool layout and able to initiate possible countermeasures. Part defects, such as weld lines or voids, often occur in the early phase of component development. By means of the available filling results, sectional views or even XY-curves as well as various reporting options, possible design adjustments and wall thickness optimizations can be analyzed. These can then be discussed amongst the design team and further developed.

In order to demonstrate the full range of Moldex3D, the leading 3D CAE software package for the analysis, design and optimization of the component, tool and process, one will receive the complete functionality of the entire CAE package (including packing, temperature control and warpage etc.) as a free trial version immediately when purchasing an entry-level basic module until the end of the year. This provides the opportunity to test the software in detail. At the end of the year, one can then decide whether to switch to the complete simulation package or to continue to use the basic module.

Interested?

Please contact us: + 49 (0)241-565 276-0 or send us an email to info@simpatec.com .