Foaming: Modified model to model the pore size during packing

ESPECIALLY FOR OUR USERS

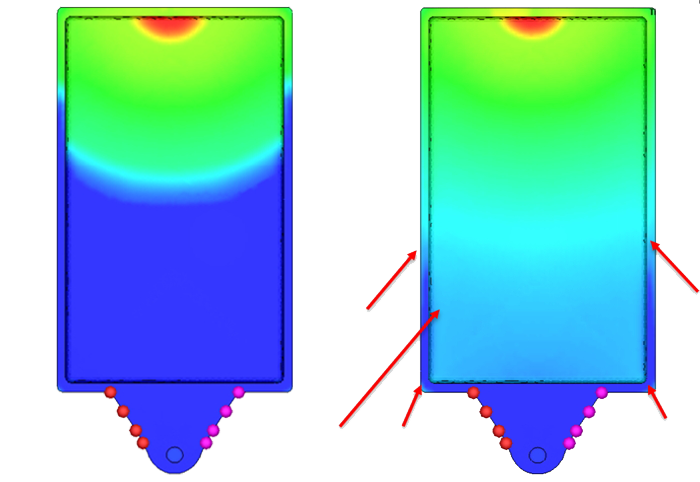

In foaming the pore size is one of the most important characteristics of the molded part to be produced. The cavity pressure significantly influences the size of the pores. The modified model of Han and Yoo enables the precise prediction of the pore size via the pressure distribution in the mold. This accounts especially for the modeling of the behavior of the pore size during packing, which also makes the core-back process possible.

One of the essential characterization features of foaming is the pore size achieved during production. In injection-molded foaming pores are normally formed by the homogeneous mixture of a physical blowing agent, usually supercritical N2 or CO2, and the polymer melt. The pores are formed by the pressure drop between the plasticizing unit and the mold where the blowing agent changes from the supercritical phase to the gas phase. The size of the pores is affected by the internal pressure in the mold. The modified model of Han and Yoo allows a much more accurate prediction of the pore size via the pressure distribution in the mold.

It is particularly possible to model more accurately the renewed reduction in pore size as packing increases. Thus, the pores are not eliminated as pressure increases (pore size =0) like it was done in the previous model of Han and Yoo. This model adjustment is particularly important when using the core-back process, since a high packing pressure and thus pore shrinkage is generated here in order to achieve a more homogeneous component structure when the pressure drops again.

Deeper insights are of interest!

Please contact us: + 49 (0)241-565 276-0 or send us an email to info@simpatec.com.