Deformations and stresses in the component - "put an end to it"

EXPERT-TIP

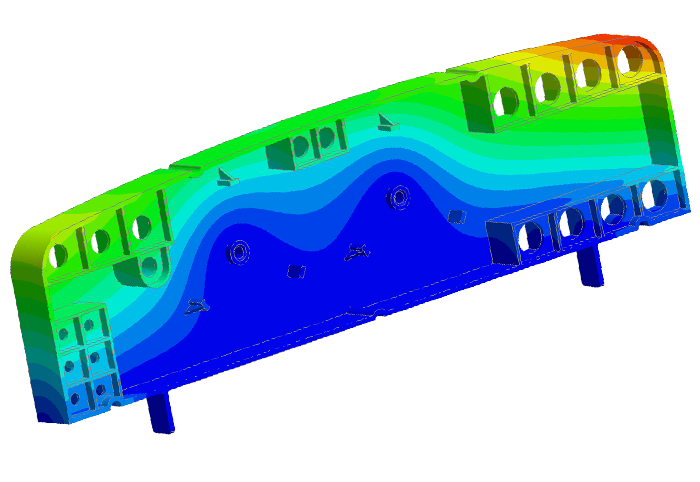

Stress analysis has been mainly applied for designers to observe stress distribution inside parts and part inserts. The stress distribution has a significant impact on part quality and structural strength, influenced by many molding factors, including temperature, force, part shape and size, material properties, etc. The stress over safety loading may destroy structural strength and cause breakage on the part. Therefore, obtaining accurate stress analysis results upfront is crucial for designers to reduce fatigue failure and extend product life cycle.

Advantages of the Moldex3D Stress module:

_ Predict potential deformation problems to evaluate material properties and process conditions

_ Consider fiber orientation effect that will affect shrinkage and part strength

_ Predict the displacement of inserts due to non-uniform flow-induced pressure with accurate 2-way Fluid Structure Interaction (FSI) consideration for Core Shift behavior of MCM, as well as Wire Sweep and Paddle Shift behaviors of IC Packaging

_ Consider welding line effect to provide more accurate prediction on strength reduction

It is worthwhile to inform yourself! Feel free to contact us at 0241 565 276-0 or send an email to sales@simpatec.com.